If you produce a large amount of grain on an annual basis, you may be using a disc pelletizer. These are granulators, designed in the form of the pan, that are able to produce this fertilizer through rotation and agitation of the pan itself. You can use these discs on a continual basis. Depending upon the manufacturer, they can last for what could be as long as several decades. However, if you want to produce good-quality organic fertilizer, you will need to have the best disc pelletizer on the market so that your business can benefit.

How Do Disc Pelletizers Work?

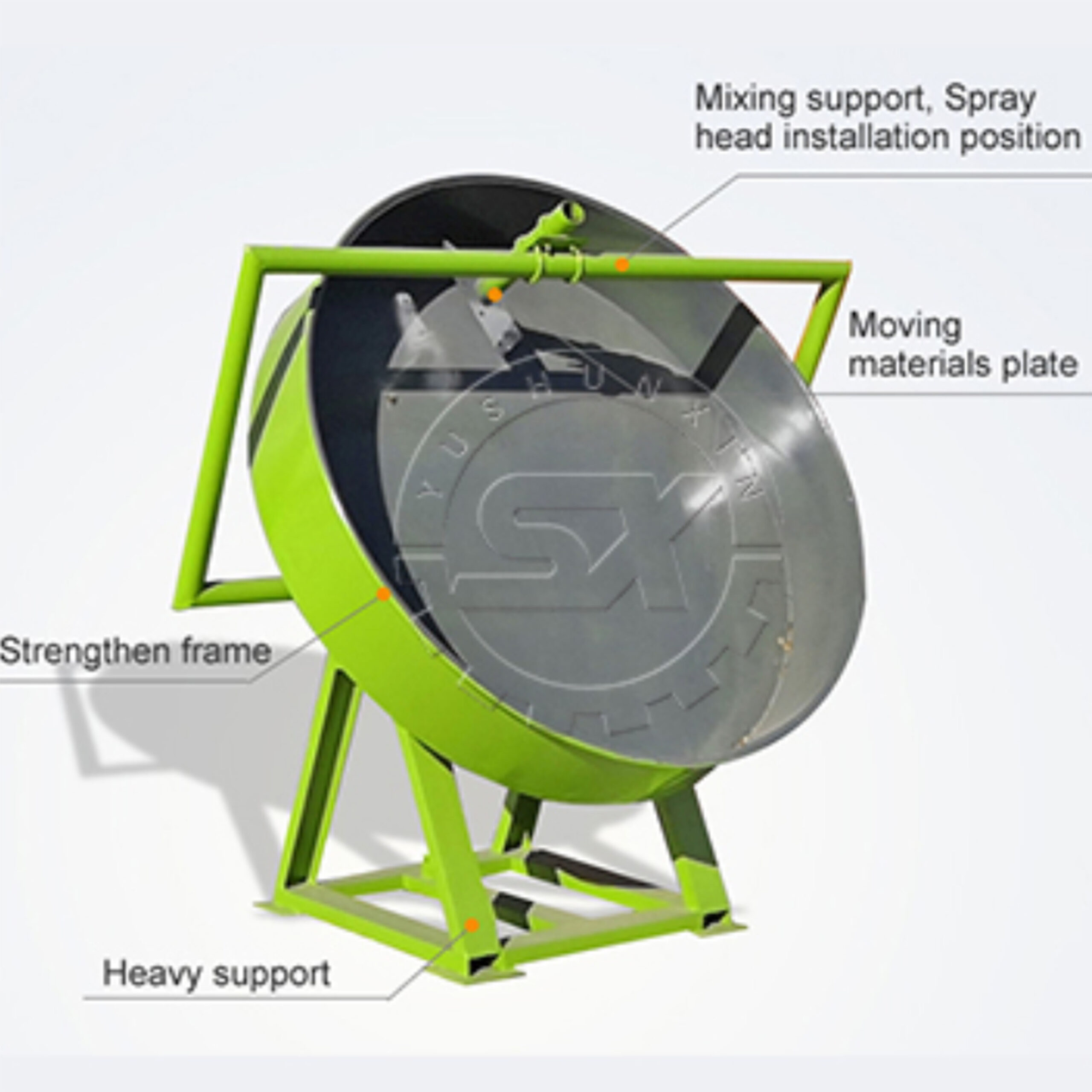

The material for the fertilizer that you are going to be producing is going to make its way onto the pan. The pan granulator is going to be spinning at a rapid pace, at an angle, so that the pellets can be produced. As it spins, the globules of the material will condense together. This will lead to the production of organic fertilizer pellets that you will use for your farm. You can also use a refined granulator product of any sort to obtain higher levels of productivity if a single disc pelletizer is not enough.

Dick granulating machine for making fertilizer

How To Get The Best Diameter For Your Pellets

There are a couple of settings and measurements to consider when choosing a pan granulator. First of all, you must consider the diameter of the pan itself. There is an adjustable switch for the speed at which the pan is going to spin. You can also adjust, typically manually, the angle of the pan. The other thing to consider when trying to reach a specific capacity of disc pelletizer , pellets size, and shape of the pellets, is the type of material that you are using. However, if you are just looking for the best diameter, the speed of the pan granulator can often affect how wide or narrow the diameter is going to be.

Further Things To Consider When Using A Pan Granulator

There are other considerations to make when trying to create a specific amount of fertilizer in the form of pellets. You must consider feedstock bulk density, the preconditioning of that material, and just tell corrosive or abrasive that material will be. In fact, most of the disc pelletizers that you are going to use are made with a material called carbon steel. You may want to switch over to stainless steel instead if you are not getting the high results that you are expecting when producing this fertilizer. You could also get a larger diameter of disc granulating machine and achieve a similar purpose.

Pan granulating machine for sale

Whether you are creating fertilizer, pesticides, or some other type of pellets, a disc pelletizer is a great tool to create these materials. Always consider safety as your top priority when producing these pellets. The fabrication technique of pan granulator, as well as the level of dust involved in this process, must be a consideration before you begin. To keep everyone safe, simply follow the recommended guidelines for the type of material to use and how to set up the entire system. Finally, consider the type of binding material that you will be using with the pellets to ensure that your disc pelletizer can produce organic fertilizer pellets that will be easy to use and package.

compound fertilizer granulating machinefertilizer granulation plantNPK fertilizer granulating machineorganic fertilizer granulating machinepan granulator for sale

The Best Disk Pelletizer For Quality Organic Fertilizer Production

April 10, 2022

fertilizer equipment, Fertilizer Factory, Fertilizer Granulating Machine, fertilizer granulator, fertilizer making, fertilizer making machine, Fertilizer Plant, fertilizer processing, fertillizer production line, making organic fertilizer, organic fertilizer granulator, Organic Fertilizer Wet Granulating

Comments Off on The Best Disk Pelletizer For Quality Organic Fertilizer Production

cs

If you produce a large amount of grain on an annual basis, you may be using a disc pelletizer. These are granulators, designed in the form of the pan, that are able to produce this fertilizer through rotation and agitation of the pan itself. You can use these discs on a continual basis. Depending upon the manufacturer, they can last for what could be as long as several decades. However, if you want to produce good-quality organic fertilizer, you will need to have the best disc pelletizer on the market so that your business can benefit.

How Do Disc Pelletizers Work?

The material for the fertilizer that you are going to be producing is going to make its way onto the pan. The pan granulator is going to be spinning at a rapid pace, at an angle, so that the pellets can be produced. As it spins, the globules of the material will condense together. This will lead to the production of organic fertilizer pellets that you will use for your farm. You can also use a refined granulator product of any sort to obtain higher levels of productivity if a single disc pelletizer is not enough.

Dick granulating machine for making fertilizer

How To Get The Best Diameter For Your Pellets

There are a couple of settings and measurements to consider when choosing a pan granulator. First of all, you must consider the diameter of the pan itself. There is an adjustable switch for the speed at which the pan is going to spin. You can also adjust, typically manually, the angle of the pan. The other thing to consider when trying to reach a specific capacity of disc pelletizer , pellets size, and shape of the pellets, is the type of material that you are using. However, if you are just looking for the best diameter, the speed of the pan granulator can often affect how wide or narrow the diameter is going to be.

Further Things To Consider When Using A Pan Granulator

There are other considerations to make when trying to create a specific amount of fertilizer in the form of pellets. You must consider feedstock bulk density, the preconditioning of that material, and just tell corrosive or abrasive that material will be. In fact, most of the disc pelletizers that you are going to use are made with a material called carbon steel. You may want to switch over to stainless steel instead if you are not getting the high results that you are expecting when producing this fertilizer. You could also get a larger diameter of disc granulating machine and achieve a similar purpose.

Pan granulating machine for sale

Whether you are creating fertilizer, pesticides, or some other type of pellets, a disc pelletizer is a great tool to create these materials. Always consider safety as your top priority when producing these pellets. The fabrication technique of pan granulator, as well as the level of dust involved in this process, must be a consideration before you begin. To keep everyone safe, simply follow the recommended guidelines for the type of material to use and how to set up the entire system. Finally, consider the type of binding material that you will be using with the pellets to ensure that your disc pelletizer can produce organic fertilizer pellets that will be easy to use and package.

compound fertilizer granulating machinefertilizer granulation plantNPK fertilizer granulating machineorganic fertilizer granulating machinepan granulator for sale