Efficient organic fertilizer manufacturing requires careful evaluation of raw materials, granulation techniques, and machinery selection. Granules and particles not only affect fertilizer quality, but also significantly shape the organic fertilizer production plant cost structure. Understanding their impact enables investors and plant owners to optimize the organic fertilizer factory cost and improve overall benefits.

What Raw Materials Are Suitable for Organic Fertilizer Granulation or Pelletizing Procedures?

Raw material selection plays a fundamental role in the organic fertilizer granule production process. Commonly, materials such as poultry manure, cattle manure, pig manure, sheep manure, and crop straw serve as primary sources for organic fertilizer granulation procedures. In addition, by-products including sugar residue, mushroom residue, filter mud, distiller’s grains, and green plant residues provide alternative options for fertilizer ball making production. Each type of material shows different moisture content, fiber structure, and nutrient composition, which directly impacts the effectiveness of the granulating machine and the final organic fertilizer pellet quality. For example, poultry manure, with its rich nutrient content and moderate viscosity, suits most common pellet making machinery for organic fertilizer. However, materials with high straw content may require pre-treatment using a crushing machine to ensure consistent particle size before entering the granulator or pelletizer. Consequently, raw material choice not only influences the fertilizer granulation process, but also determines the investment and operation costs of the entire production line.

Organic Fertilizer Raw Materials

How Do Different Organic Fertilizer Granulation Machines Affect Production Plant Cost?

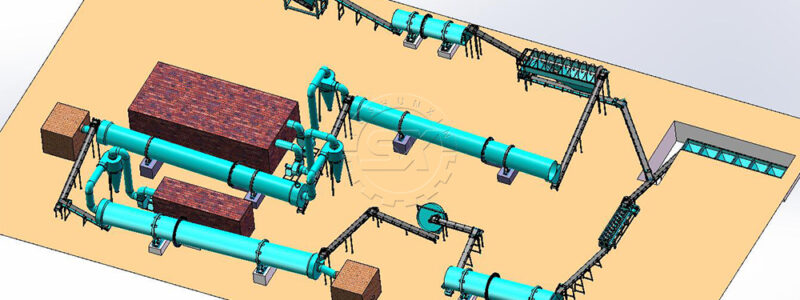

Various types of organic fertilizer granulating equipment and corresponding process arrangements significantly influence organic fertilizer plant setup costs. For instance, disc granulators and new type organic fertilizer granulators generally require simpler installation and moderate energy consumption, presenting a cost-effective solution for small and medium-scale organic fertilizer pellet making factories. Drum granulators and rotary pelletizing systems, with their higher throughput and automation levels, suit larger-scale organic fertilizer manufacturing plants, but demand greater investment in machinery and plant infrastructure. Double roller extrusion granulators enable low-temperature, dry granulation processes, which save on drying costs but often require strict control of raw material moisture and particle size. Additionally, the inclusion of related equipment—such as a batching machine for proportional material feeding, a rotary drying machine for moisture regulation, and a screening machine for particle size sorting—adds to the overall organic fertilizer production plant cost. Each equipment choice must align with the desired organic fertilizer granule specifications, production scale, and budget requirements, ensuring cost-effectiveness in fertilizer production procedures.

How Do Granule and Particle Characteristics Influence Organic Fertilizer Plant Operating Costs?

Granule and particle characteristics, such as size uniformity, hardness, and moisture content, directly affect downstream processing costs and the market value of organic fertilizer products. Uniform and compact organic fertilizer pellets reduce product losses during packaging and transportation, enhance storage stability, and improve market competitiveness. However, achieving consistent granule or pellet quality requires precise control throughout the granulation and drying process stages. Equipment such as rotary drying machines and vibrating screening machines become essential for adjusting particle moisture and grading granule sizes. Process control systems may further increase the fertilizer manufacturing plant cost, but they guarantee a higher finished product rate and reduced waste. When plant operators focus on optimizing granulation procedures and maintaining stable particle quality, they ensure lower maintenance expenses, higher yields, and a quicker return on investment for the organic fertilizer production plant.

Conclusion

Ultimately, selecting suitable raw materials, optimizing granulation process flow, and investing in the right organic fertilizer pellet making equipment remain crucial for controlling fertilizer plant costs. Granule and particle characteristics must align with market demand and plant-scale expectations. Investors and plant managers should weigh the initial fertilizer plant setup cost against long-term operational expenses, product quality, and market positioning. Professional equipment manufacturers, such as Yushunxin, offer tailored solutions and advanced organic fertilizer granulation machinery to help clients reduce manufacturing costs while maximizing efficiency and product value. By focusing on integrated process design and innovative equipment selection, stakeholders can ensure lasting competitiveness in the organic fertilizer production industry. You can visit: https://www.fertilizerproductequipment.com/organic-fertilizer-production-plant-cost/

Organic Fertilizer Plant Costorganic fertilizer plant setup

How Do Granules and Particles Influence Organic Fertilizer Manufacturing Costs?

August 11, 2025

Organic Fertilizer Plant Cost, Organic Fertilizer Production, Organic fertilizer production budget

Comments Off on How Do Granules and Particles Influence Organic Fertilizer Manufacturing Costs?

cs

Efficient organic fertilizer manufacturing requires careful evaluation of raw materials, granulation techniques, and machinery selection. Granules and particles not only affect fertilizer quality, but also significantly shape the organic fertilizer production plant cost structure. Understanding their impact enables investors and plant owners to optimize the organic fertilizer factory cost and improve overall benefits.

What Raw Materials Are Suitable for Organic Fertilizer Granulation or Pelletizing Procedures?

Raw material selection plays a fundamental role in the organic fertilizer granule production process. Commonly, materials such as poultry manure, cattle manure, pig manure, sheep manure, and crop straw serve as primary sources for organic fertilizer granulation procedures. In addition, by-products including sugar residue, mushroom residue, filter mud, distiller’s grains, and green plant residues provide alternative options for fertilizer ball making production. Each type of material shows different moisture content, fiber structure, and nutrient composition, which directly impacts the effectiveness of the granulating machine and the final organic fertilizer pellet quality. For example, poultry manure, with its rich nutrient content and moderate viscosity, suits most common pellet making machinery for organic fertilizer. However, materials with high straw content may require pre-treatment using a crushing machine to ensure consistent particle size before entering the granulator or pelletizer. Consequently, raw material choice not only influences the fertilizer granulation process, but also determines the investment and operation costs of the entire production line.

Organic Fertilizer Raw Materials

How Do Different Organic Fertilizer Granulation Machines Affect Production Plant Cost?

Various types of organic fertilizer granulating equipment and corresponding process arrangements significantly influence organic fertilizer plant setup costs. For instance, disc granulators and new type organic fertilizer granulators generally require simpler installation and moderate energy consumption, presenting a cost-effective solution for small and medium-scale organic fertilizer pellet making factories. Drum granulators and rotary pelletizing systems, with their higher throughput and automation levels, suit larger-scale organic fertilizer manufacturing plants, but demand greater investment in machinery and plant infrastructure. Double roller extrusion granulators enable low-temperature, dry granulation processes, which save on drying costs but often require strict control of raw material moisture and particle size. Additionally, the inclusion of related equipment—such as a batching machine for proportional material feeding, a rotary drying machine for moisture regulation, and a screening machine for particle size sorting—adds to the overall organic fertilizer production plant cost. Each equipment choice must align with the desired organic fertilizer granule specifications, production scale, and budget requirements, ensuring cost-effectiveness in fertilizer production procedures.

How Do Granule and Particle Characteristics Influence Organic Fertilizer Plant Operating Costs?

Granule and particle characteristics, such as size uniformity, hardness, and moisture content, directly affect downstream processing costs and the market value of organic fertilizer products. Uniform and compact organic fertilizer pellets reduce product losses during packaging and transportation, enhance storage stability, and improve market competitiveness. However, achieving consistent granule or pellet quality requires precise control throughout the granulation and drying process stages. Equipment such as rotary drying machines and vibrating screening machines become essential for adjusting particle moisture and grading granule sizes. Process control systems may further increase the fertilizer manufacturing plant cost, but they guarantee a higher finished product rate and reduced waste. When plant operators focus on optimizing granulation procedures and maintaining stable particle quality, they ensure lower maintenance expenses, higher yields, and a quicker return on investment for the organic fertilizer production plant.

Conclusion

Ultimately, selecting suitable raw materials, optimizing granulation process flow, and investing in the right organic fertilizer pellet making equipment remain crucial for controlling fertilizer plant costs. Granule and particle characteristics must align with market demand and plant-scale expectations. Investors and plant managers should weigh the initial fertilizer plant setup cost against long-term operational expenses, product quality, and market positioning. Professional equipment manufacturers, such as Yushunxin, offer tailored solutions and advanced organic fertilizer granulation machinery to help clients reduce manufacturing costs while maximizing efficiency and product value. By focusing on integrated process design and innovative equipment selection, stakeholders can ensure lasting competitiveness in the organic fertilizer production industry. You can visit: https://www.fertilizerproductequipment.com/organic-fertilizer-production-plant-cost/

Organic Fertilizer Plant Costorganic fertilizer plant setup