Tag: Organic Fertilizer Plant Cost

How Do Granules and Particles Influence Organic Fertilizer Manufacturing Costs?

Efficient organic fertilizer manufacturing requires careful evaluation of raw materials, granulation techniques, and machinery selection. Granules and particles not only affect fertilizer quality, but also significantly shape the organic fertilizer production plant cost structure. Understanding their impact enables investors and plant owners to optimize the organic fertilizer factory cost and improve overall benefits.

What Raw Materials Are Suitable for Organic Fertilizer Granulation or Pelletizing Procedures?

Raw material selection plays a fundamental role in the organic fertilizer granule production process. Commonly, materials such as poultry manure, cattle manure, pig manure, sheep manure, and crop straw serve as primary sources for organic fertilizer granulation procedures. In addition, by-products including sugar residue, mushroom residue, filter mud, distiller’s grains, and green plant residues provide alternative options for fertilizer ball making production. Each type of material shows different moisture content, fiber structure, and nutrient composition, which directly impacts the effectiveness of the granulating machine and the final organic fertilizer pellet quality. For example, poultry manure, with its rich nutrient content and moderate viscosity, suits most common pellet making machinery for organic fertilizer. However, materials with high straw content may require pre-treatment using a crushing machine to ensure consistent particle size before entering the granulator or pelletizer. Consequently, raw material choice not only influences the fertilizer granulation process, but also determines the investment and operation costs of the entire production line.

Organic Fertilizer Raw Materials

How Do Different Organic Fertilizer Granulation Machines Affect Production Plant Cost?

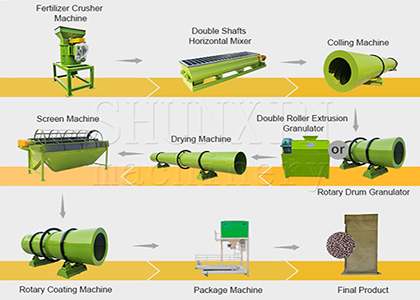

Various types of organic fertilizer granulating equipment and corresponding process arrangements significantly influence organic fertilizer plant setup costs. For instance, disc granulators and new type organic fertilizer granulators generally require simpler installation and moderate energy consumption, presenting a cost-effective solution for small and medium-scale organic fertilizer pellet making factories. Drum granulators and rotary pelletizing systems, with their higher throughput and automation levels, suit larger-scale organic fertilizer manufacturing plants, but demand greater investment in machinery and plant infrastructure. Double roller extrusion granulators enable low-temperature, dry granulation processes, which save on drying costs but often require strict control of raw material moisture and particle size. Additionally, the inclusion of related equipment—such as a batching machine for proportional material feeding, a rotary drying machine for moisture regulation, and a screening machine for particle size sorting—adds to the overall organic fertilizer production plant cost. Each equipment choice must align with the desired organic fertilizer granule specifications, production scale, and budget requirements, ensuring cost-effectiveness in fertilizer production procedures.

How Do Granule and Particle Characteristics Influence Organic Fertilizer Plant Operating Costs?

Granule and particle characteristics, such as size uniformity, hardness, and moisture content, directly affect downstream processing costs and the market value of organic fertilizer products. Uniform and compact organic fertilizer pellets reduce product losses during packaging and transportation, enhance storage stability, and improve market competitiveness. However, achieving consistent granule or pellet quality requires precise control throughout the granulation and drying process stages. Equipment such as rotary drying machines and vibrating screening machines become essential for adjusting particle moisture and grading granule sizes. Process control systems may further increase the fertilizer manufacturing plant cost, but they guarantee a higher finished product rate and reduced waste. When plant operators focus on optimizing granulation procedures and maintaining stable particle quality, they ensure lower maintenance expenses, higher yields, and a quicker return on investment for the organic fertilizer production plant.

Conclusion

Ultimately, selecting suitable raw materials, optimizing granulation process flow, and investing in the right organic fertilizer pellet making equipment remain crucial for controlling fertilizer plant costs. Granule and particle characteristics must align with market demand and plant-scale expectations. Investors and plant managers should weigh the initial fertilizer plant setup cost against long-term operational expenses, product quality, and market positioning. Professional equipment manufacturers, such as Yushunxin, offer tailored solutions and advanced organic fertilizer granulation machinery to help clients reduce manufacturing costs while maximizing efficiency and product value. By focusing on integrated process design and innovative equipment selection, stakeholders can ensure lasting competitiveness in the organic fertilizer production industry. You can visit: https://www.fertilizerproductequipment.com/organic-fertilizer-production-plant-cost/

6 Factors Affects Organic Fertilizer Production Plant Cost

When it comes to organic farming, the role of fertilizers cannot be overstated. With the growing demand for sustainable agriculture, organic fertilizer production has become a viable business opportunity. However, before venturing into this green industry, it’s crucial to understand the costs involved in setting up an organic fertilizer production plant. In general, the cost of organic fertilizer making contains 6 aspects:

Initial Investment of land and infrastructure

The journey begins with the initial investment – acquiring the land and constructing the plant. Land costs vary widely depending on location, while construction costs depend on the plant’s size and the materials used. On top of this, you’ll need to consider the price for obtaining necessary permits and meeting local regulations.

Equipment and Technology

A substantial part of the investment will go into buy organic fertilizer equipment. This can range from simple organic waste compost turners to sophisticated organic fertilizer granulators and packaging machines. The technology and machinery required for producing organic fertilizer are significant cost factors, with state-of-the-art equipment driving up the price. Click here to learn more.

Raw Materials

Raw materials such as manure, agricultural waste, and food compost are the lifeline of an organic fertilizer plant. Because they contains rich elements of Nitrogen, Phosphorus and Potassium, etc.While some raw materials can be sourced inexpensively or even free, transportation and processing costs can add up. Establishing a reliable, cost-effective supply chain is a major component of managing production costs.

Labor

Skilled and unskilled labor also accounts for a portion of the production costs. From operators for machinery to administrative staff, payroll expenses must be factored into the total cost. But, if you are invest in organic fertilizer production line with high automation, it only needs a low payment for employment.

Operational Expenses

Setup an organic fertilizer plant involves several operational expenses. These include energy consumption, water usage, maintenance of equipment, and logistics. Additionally, marketing and sales efforts to promote the product can be considerable, especially when building a brand and customer base from scratch.

Compliance and Sustainability

Lastly, compliance with environmental regulations and sustainability certifications can incur costs. However, these are essential expenses, ensuring that the plant operates within legal frameworks and meets the standards demanded by consumers and retailers.

Conclusion

Starting an organic fertilizer production plant is not a decision to be taken lightly. While the organic trend shows no sign of slowing down, and the potential profits can be tempting, it’s imperative to thoroughly analyze and plan for the associated costs. From initial setup to day-to-day operations, a well-considered budget and cost management strategy are critical to the success of an organic fertilizer production business. Aspiring entrepreneurs should conduct detailed market research, consult with industry experts, and possibly start with a pilot project before scaling up to full production. With careful planning and management, an organic fertilizer plant can become a sustainable, profitable enterprise that contributes to a greener future. If you need more precise quote for organic fertilizer plant setup and machines, you can visit https://www.fertilizerbusinessplan.com/investment-of-organic-fertilizer-plant-setup/

What Is Price to Build A Fertilizer Factory?

Building a fertilizer factory is a significant investment that can lead to considerable profits for those in the agricultural industry. The cost can vary greatly depending on several key factors, including the type of fertilizer one intends to produce, the scale of the operation, and the degree of automation required. With a variety of budget options and scales, you need to choose a reliable manufacturer for comprehensive fertilizer production plans, catering to both organic fertilizer and compound fertilizer in powder or granulation form.

Organic Fertilizer Production Proposal

For those exploring the potential of starting an organic fertilizer production, Yushunxin presents a range of solutions that can transform locally sourced organic waste materials into high-quality fertilizer. These production lines are carefully designed to optimize material use, helping to convert animal manure, agricultural waste, and municipal sludge into valuable, eco-friendly products.

Entrepreneurs or businesses looking at a small to medium scale organic fertilizer plant setup can select a powder organic fertilizer production line. Costs can range from $30,000 to $100,000, making it a highly accessible entry point into the market.

Organic fertilizer plant setup cost

Compound Fertilizer Plant Setup

For compound fertilizer production, Yushunxin’s plans are meticulously tailored to ensure precise formulations of NPK fertilizers. Their compound fertilizer lines are equipped with cutting-edge technology for batching, blending, granulating, drying, and packaging – all crucial steps that define the quality of the end product.

A small-scale compound fertilizer granulation line could require an investment of $100,000, while a larger operation might need an investment upwards of $500,000, depending on the desired level of automation and production capacity. Certainly, you can choose BB fertilizer blending line for lower costs.

NPK fertilizer manufacturing equipment for sale

Why to Buy Fertilizer Production Equipment from Yushunxin?

Offering Cost-effective Production Proposal

When considering the costs of establishing a fertilizer factory, one should not overlook the additional expenses beyond equipment procurement. These can include the cost of raw materials, utilities, labor, and ongoing maintenance. However, Yushunxin prides itself on providing energy-efficient and durable machinery, which means operational costs are as low as possible without compromising on productivity and product quality.

Offering Considerate Service

Yushunxin stands out in the market by not just supplying equipment but also partnering with clients to ensure their success in the fertilizer production industry. Their team of experts is ready to assist clients in every stage, from the initial planning and design phases all the way to the installation and operation of the factory. They work closely with clients to identify the most cost-effective and efficient production plans tailored to their specific budget and goals.

In a nutshell, whether one is just starting or seeking to expand existing operations, Yushunxin provides scalable solutions to fit various budgets. With their expertise and high-quality equipment, clients can confidently step into the fertilizer industry, knowing they have a reliable partner dedicated to their success.

Click this link for more information: https://www.fertilizerproductequipment.com/fertilizer-manufacturing-plant-cost/

Transforming Livestock Manure into Fertilizer: A Sustainable Solution

In the realm of sustainable agriculture and responsible farming, the conversion of livestock manure into fertilizer has emerged as a technology that not only benefits the farmer but also contributes to a cleaner environment and healthier crops. This innovative approach tackles the dual challenges of managing animal waste effectively and reducing the reliance on synthetic fertilizers. In this blog, we’ll delve into the technology of transforming livestock manure into valuable fertilizer and its manifold advantages.

The Manure Management Challenge

Livestock farming, an essential component of the agriculture industry, generates a significant amount of organic waste – manure. If not managed properly, this manure can become a source of environmental pollution, releasing harmful substances into the air and waterways. Moreover, it is rich in nutrients that, when harnessed efficiently, can serve as a potent organic fertilizer.

The Fertilizer Technology

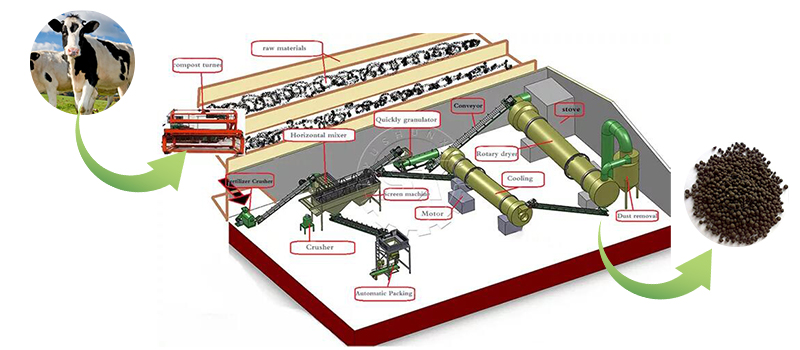

Composting

One of the most popular methods for converting manure into fertilizer is composting. This process involves the controlled decomposition of organic materials to create a nutrient-rich, stable end product. Composting manure:

- Kills Pathogens and Weed Seeds: The high temperatures reached during composting effectively neutralize harmful pathogens and weed seeds, making the fertilizer safe for use.

- Stabilizes Nutrients: Composting reduces the risk of nutrient runoff, ensuring that the valuable nutrients are retained for crop uptake.

Granulation

for commercial livestock fertilizer manufacturing, granule making can bring you more profits.

Click here for more livestock to fertilizer steps.

Nutrient Concentration Technologies

In addition to composting, there are technologies that concentrate the nutrients in manure, reducing the volume and making it easier to transport and apply. These technologies include:

- Manure Separation: This process separates solids from liquid manure, enabling the nutrients to be concentrated in a smaller volume.

Advantages of Manure-to-Fertilizer Technology

The technology for transforming livestock manure into fertilizer offers numerous benefits:

- Reduced Environmental Impact: Proper livestock manure management reduces the risk of water pollution, air pollution, and greenhouse gas emissions, mitigating the environmental footprint of livestock operations.

- Nutrient Recycling: By converting manure into fertilizer, farmers can close the nutrient cycle on their farms, reducing the need for synthetic fertilizers and saving costs.

- Improved Soil Health: Fertilizer derived from manure enhances soil structure, increases water retention, and fosters a healthier microbial community in the soil.

- Odor Mitigation: Certain manure-to-fertilizer technologies, such as aerobic fermentation of livestock manure, help mitigate the odor associated with raw manure.

- Pathogen Reduction: Composting and other treatment methods effectively reduce pathogens in the manure, making it safer for use.

Livestock manure to fertilizer

Challenges and Considerations

While the technology for converting livestock manure into fertilizer offers numerous benefits, it’s not without its challenges and considerations:

- Costs: for livestock manure to fertilizer, you need consider the costs of livestock poop fertilizer plant setup. Including equipment, workshop building, certificates, etc

- Regulations: Depending on your location, there may be regulations and permitting requirements for the handling and application of manure-based fertilizers.

Conclusion

The technology for converting livestock manure into fertilizer is a prime example of how sustainable agriculture practices can be a win-win for farmers, the environment, and consumers. By effectively managing this abundant organic resource, farmers can improve the sustainability and productivity of their operations while reducing the negative impacts of manure on the environment. As this technology continues to evolve and become more accessible, it holds the promise of a cleaner, more sustainable future for agriculture. If you are interested in it, you can visit https://www.manuremanagementplan.com/livestock-manure-management/ for details.

What Are the Startup Costs for An Organic Fertilizer Production Plant?

October 23, 2025

Organic Fertilizer Plant Cost, Organic fertilizer production budget, organic fertilizer production machine

Comments Off on What Are the Startup Costs for An Organic Fertilizer Production Plant?

cs

Establishing an organic fertilizer production plant involves careful consideration of startup costs. This endeavor requires a thorough understanding of raw materials, machinery, and overall production expenses. By examining these key factors, businesses can make informed decisions about their investment in a compound fertilizer manufacturing operation.

What Raw Materials Are Suitable for Compound Fertilizer Production?

The selection of raw materials significantly impacts the quality and cost of NPK (Nitrogen, Phosphorus, and Potassium) or compound fertilizer production. Common raw materials include animal manures, plant residues, and various minerals. Animal manures, such as chicken or cow manure, provide essential nutrients for fertilizer. Similarly, plant residues like crop straws contribute to the organic matter necessary for soil health.

Rock phosphate serves as a valuable source of phosphorus while potassium chloride supplies potassium. These materials not only enhance the nutrient profile of the final product but also affect the overall fertilizer plant cost. In addition, organic matter from composting processes improves nutrient retention and enhances soil fertility. Understanding the benefits and costs associated with these raw materials helps in optimizing production processes.

Organic Fertilizer Raw Materials

What Machinery Is Required for Fertilizer Production?

Investing in the right machinery is crucial for efficient fertilizer production. Key pieces of equipment include granulators, crushing machines, and mixing systems. A granulator is essential for transforming raw materials into pellets or granules. Different types of granulators, such as disc granulators and double roller extrusion granulators, offer unique benefits based on the production requirements.

Crushing machines play a pivotal role in preparing raw materials for granulation. These machines reduce particle sizes, facilitating better mixing and granulation. Furthermore, incorporating a batching machine ensures accurate measurements of ingredients, enhancing the consistency of the final product. The costs associated with these machines contribute significantly to the overall organic fertilizer production plant cost. Investing in high-quality equipment can lead to improved efficiency and reduced operational costs.

Equipment commonly used in bio organic fertilizer production

How Do Production Costs Affect the Overall Investment?

Understanding the various costs involved in setting up an organic fertilizer production plant is essential for potential investors. The organic fertilizer plant setup cost encompasses machinery, raw materials, labor, and facility expenses. Each component plays a vital role in determining the overall investment required for successful operation.

For instance, the cost of a granulator and associated machinery can vary widely based on brand, capacity, and features. A high-capacity granulator may require a larger initial investment but can lead to greater production efficiency and lower long-term operational costs. Additionally, labor costs must be considered, as skilled workers will be necessary to operate machinery and manage production processes effectively.

Overall, being well-informed about the fertilizer manufacturing plant cost and its components allows stakeholders to budget effectively and plan for future growth.

Conclusion

Setting up an organic fertilizer production plant involves navigating various costs related to raw materials and machinery. Understanding the types of raw materials suitable for NPK and compound fertilizer production, along with the essential equipment required, is crucial for making sound investment decisions. By analyzing these factors, businesses can ensure they allocate resources wisely and optimize their production processes. Ultimately, investing in high-quality machinery and raw materials, such as those provided by a professional fertilizer equipment manufacturer, like Yushunxin, can lead to a successful and profitable fertilizer production operation. You can visit: https://www.fertilizerproductequipment.com/organic-fertilizer-production-plant-cost/

cost of organic fertilizer manufacturing line equipmentorganic fertilizer plantOrganic Fertilizer Plant Cost