Tag: cost of organic fertilizer manufacturing line equipment

What Is Price to Build A Fertilizer Factory?

Building a fertilizer factory is a significant investment that can lead to considerable profits for those in the agricultural industry. The cost can vary greatly depending on several key factors, including the type of fertilizer one intends to produce, the scale of the operation, and the degree of automation required. With a variety of budget options and scales, you need to choose a reliable manufacturer for comprehensive fertilizer production plans, catering to both organic fertilizer and compound fertilizer in powder or granulation form.

Organic Fertilizer Production Proposal

For those exploring the potential of starting an organic fertilizer production, Yushunxin presents a range of solutions that can transform locally sourced organic waste materials into high-quality fertilizer. These production lines are carefully designed to optimize material use, helping to convert animal manure, agricultural waste, and municipal sludge into valuable, eco-friendly products.

Entrepreneurs or businesses looking at a small to medium scale organic fertilizer plant setup can select a powder organic fertilizer production line. Costs can range from $30,000 to $100,000, making it a highly accessible entry point into the market.

Organic fertilizer plant setup cost

Compound Fertilizer Plant Setup

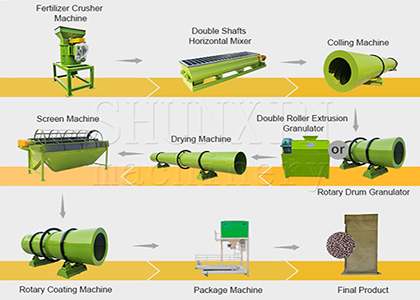

For compound fertilizer production, Yushunxin’s plans are meticulously tailored to ensure precise formulations of NPK fertilizers. Their compound fertilizer lines are equipped with cutting-edge technology for batching, blending, granulating, drying, and packaging – all crucial steps that define the quality of the end product.

A small-scale compound fertilizer granulation line could require an investment of $100,000, while a larger operation might need an investment upwards of $500,000, depending on the desired level of automation and production capacity. Certainly, you can choose BB fertilizer blending line for lower costs.

NPK fertilizer manufacturing equipment for sale

Why to Buy Fertilizer Production Equipment from Yushunxin?

Offering Cost-effective Production Proposal

When considering the costs of establishing a fertilizer factory, one should not overlook the additional expenses beyond equipment procurement. These can include the cost of raw materials, utilities, labor, and ongoing maintenance. However, Yushunxin prides itself on providing energy-efficient and durable machinery, which means operational costs are as low as possible without compromising on productivity and product quality.

Offering Considerate Service

Yushunxin stands out in the market by not just supplying equipment but also partnering with clients to ensure their success in the fertilizer production industry. Their team of experts is ready to assist clients in every stage, from the initial planning and design phases all the way to the installation and operation of the factory. They work closely with clients to identify the most cost-effective and efficient production plans tailored to their specific budget and goals.

In a nutshell, whether one is just starting or seeking to expand existing operations, Yushunxin provides scalable solutions to fit various budgets. With their expertise and high-quality equipment, clients can confidently step into the fertilizer industry, knowing they have a reliable partner dedicated to their success.

Click this link for more information: https://www.fertilizerproductequipment.com/fertilizer-manufacturing-plant-cost/

What Is The Cost Of Large Scale Organic Fertilizer Manufacturing

The cost of large-scale organic fertilizer manufacturing can vary depending on several factors, including the production capacity, technology and equipment used, raw material availability, labor costs, and operational expenses. Here are some key cost considerations for large-scale organic fertilizer manufacturing:

Facility and Equipment

The cost of establishing a manufacturing facility for large scale organic fertilizer production can be significant. This includes the construction or acquisition of production buildings, storage facilities, and infrastructure such as water supply and electricity. The cost of purchasing or leasing the necessary large scale fertilizer making equipment, such as mixers, granulators, dryers, and packaging machines, should also be taken into account. Click here to know more

Raw Materials

The availability and cost of raw materials used in organic fertilizer production can vary depending on factors such as geographic location and seasonality. Organic fertilizer raw materials typically include animal manure, crop residues, food waste, and other organic matter. The cost of sourcing these materials can fluctuate based on market conditions and transportation expenses.

Labor and Staffing

The number of employees required for large-scale organic fertilizer preparation will depend on the size of the facility and the production processes involved. Labor costs, including wages, benefits, and training, should be factored into the overall cost calculations.

Utilities and Energy

Manufacturing processes such as mixing, granulating, drying, and packaging require energy inputs. The cost of electricity, fuel, and other utilities needed for operating the facility should be considered. It also plays an important role of organic fertilizer making cost

Quality Control and Testing

Quality control measures, including regular testing and analysis of raw materials and finished products, should be implemented to ensure compliance with quality standards. The cost of quality control measures, including laboratory equipment, testing services, and personnel, should be factored in.

Regulatory Compliance

Compliance with environmental regulations, occupational health and safety standards, and other legal requirements can entail additional costs. This may include obtaining permits, implementing pollution control measures, and meeting reporting and record-keeping obligations.

Marketing and Distribution

The cost of marketing and distribution should be considered to promote and sell the manufactured organic fertilizers. This may include branding, packaging, advertising, and transportation expenses.

It’s important to conduct a thorough feasibility study and cost analysis specific to your location, scale of operation, and business model to determine the accurate cost of large-scale organic fertilizer manufacturing. Consulting with industry experts and conducting market research can also provide valuable insights into cost estimation and profitability projections. And if you want to learn more about large scale organic fertilizer manufacturing, you can visit https://www.fertilizerbusinessplan.com/how-to-make-organic-fertilizer-in-a-large-scale/

What Are the Startup Costs for An Organic Fertilizer Production Plant?

October 23, 2025

Organic Fertilizer Plant Cost, Organic fertilizer production budget, organic fertilizer production machine

Comments Off on What Are the Startup Costs for An Organic Fertilizer Production Plant?

cs

Establishing an organic fertilizer production plant involves careful consideration of startup costs. This endeavor requires a thorough understanding of raw materials, machinery, and overall production expenses. By examining these key factors, businesses can make informed decisions about their investment in a compound fertilizer manufacturing operation.

What Raw Materials Are Suitable for Compound Fertilizer Production?

The selection of raw materials significantly impacts the quality and cost of NPK (Nitrogen, Phosphorus, and Potassium) or compound fertilizer production. Common raw materials include animal manures, plant residues, and various minerals. Animal manures, such as chicken or cow manure, provide essential nutrients for fertilizer. Similarly, plant residues like crop straws contribute to the organic matter necessary for soil health.

Rock phosphate serves as a valuable source of phosphorus while potassium chloride supplies potassium. These materials not only enhance the nutrient profile of the final product but also affect the overall fertilizer plant cost. In addition, organic matter from composting processes improves nutrient retention and enhances soil fertility. Understanding the benefits and costs associated with these raw materials helps in optimizing production processes.

Organic Fertilizer Raw Materials

What Machinery Is Required for Fertilizer Production?

Investing in the right machinery is crucial for efficient fertilizer production. Key pieces of equipment include granulators, crushing machines, and mixing systems. A granulator is essential for transforming raw materials into pellets or granules. Different types of granulators, such as disc granulators and double roller extrusion granulators, offer unique benefits based on the production requirements.

Crushing machines play a pivotal role in preparing raw materials for granulation. These machines reduce particle sizes, facilitating better mixing and granulation. Furthermore, incorporating a batching machine ensures accurate measurements of ingredients, enhancing the consistency of the final product. The costs associated with these machines contribute significantly to the overall organic fertilizer production plant cost. Investing in high-quality equipment can lead to improved efficiency and reduced operational costs.

Equipment commonly used in bio organic fertilizer production

How Do Production Costs Affect the Overall Investment?

Understanding the various costs involved in setting up an organic fertilizer production plant is essential for potential investors. The organic fertilizer plant setup cost encompasses machinery, raw materials, labor, and facility expenses. Each component plays a vital role in determining the overall investment required for successful operation.

For instance, the cost of a granulator and associated machinery can vary widely based on brand, capacity, and features. A high-capacity granulator may require a larger initial investment but can lead to greater production efficiency and lower long-term operational costs. Additionally, labor costs must be considered, as skilled workers will be necessary to operate machinery and manage production processes effectively.

Overall, being well-informed about the fertilizer manufacturing plant cost and its components allows stakeholders to budget effectively and plan for future growth.

Conclusion

Setting up an organic fertilizer production plant involves navigating various costs related to raw materials and machinery. Understanding the types of raw materials suitable for NPK and compound fertilizer production, along with the essential equipment required, is crucial for making sound investment decisions. By analyzing these factors, businesses can ensure they allocate resources wisely and optimize their production processes. Ultimately, investing in high-quality machinery and raw materials, such as those provided by a professional fertilizer equipment manufacturer, like Yushunxin, can lead to a successful and profitable fertilizer production operation. You can visit: https://www.fertilizerproductequipment.com/organic-fertilizer-production-plant-cost/

cost of organic fertilizer manufacturing line equipmentorganic fertilizer plantOrganic Fertilizer Plant Cost