Category: chemical fertilizer making

How to Make Zeolite Granules in Rotary Drum Granulation Machine?

Zeolite is a versatile and highly sought-after mineral due to its unique molecular structure and various applications in industries such as agriculture, water treatment, and chemical manufacturing. Zeolite granules, formed through a granulation process, offer improved handling and application properties compared to their powdered counterparts. In this guide, we will explore the process of making zeolite granules using a rotary drum granulation machine, a widely used equipment for large-scale production.

Understanding the Rotary Drum Granulation Machine

The rotary drum granulation machine is a mechanical device specifically designed for the granulation of materials in a continuous and controlled manner. It consists of a rotating drum with internal lifting flights or agitators that tumble and mix the feed material while facilitating the granulation process. The machine operates based on the principles of agglomeration, where fine particles are bonded together to form larger, more durable granules.

Step 1: Preparing the Zeolite Feed

The first step in the granulation process is preparing the zeolite feed material. Zeolite, in its powdered form, is typically used as the starting material. It is essential to ensure that the zeolite powder is of consistent particle size and free from any contaminants or impurities that may hinder the granulation process. If necessary, the zeolite powder can be sieved or subjected to other pre-processing steps to meet the desired specifications.

Step 2: Adjusting the Granulation Parameters

To achieve optimal granulation results, it is crucial to adjust the granulation parameters of the rotary drum granulation machine. These parameters include drum speed, angle of inclination, residence time, and the addition of granulation aids or binders. The drum speed determines the intensity of the mixing and impact forces, while the angle of inclination influences the trajectory and movement of the zeolite particles within the drum. The residence time determines how long the zeolite particles are exposed to the granulation process.

Step 3: Adding Binders or Granulation Aids

In some cases, the addition of binders or granulation aids may be necessary to improve the agglomeration of zeolite particles and enhance the strength of the resulting granules. Binders can be organic or inorganic materials that act as adhesive agents, promoting the binding of zeolite particles. Granulation aids, on the other hand, can include liquids or powders that aid in the granulation process by providing lubrication or promoting particle adhesion.

Step 4: Granulation Process

Once the granulation parameters have been set and any necessary binders or granulation aids have been added, the rotary drum granulation machine can be started. The drum’s rotation causes the zeolite particles to collide, tumble, and mix, resulting in the formation of granules. The impact forces generated during the process facilitate the agglomeration of the zeolite particles, leading to the growth of granules. The residence time within the drum allows the granules to solidify and reach the desired size and strength.

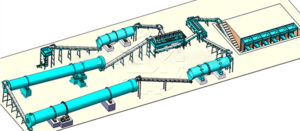

rotary drum granulator production line

Step 5: Drying and Cooling

After the granulation process is complete, the newly formed zeolite granules are typically moist and require drying and cooling. Drying removes the excess moisture from the granules, ensuring their stability and preventing degradation during storage. Cooling the granules helps to reduce their temperature and minimize the risk of caking or agglomeration during subsequent handling or packaging processes.

Step 6: Sieving and Packaging

The final step in the production of zeolite granules involves sieving the dried and cooled granules to remove any oversized or undersized particles, ensuring uniformity in size. The granules are then ready for packaging, which can be done in various forms such as bags, drums, or bulk containers, depending on the intended application.

Conclusion

Zeolite granules produced through rotary drum granulation offer enhanced handling, improved flow properties, and controlled release characteristics, making them ideal for a wide range of applications. By following the steps outlined in this guide and carefully adjusting the granulation parameters, it is possible to produce high-quality zeolite granules that meet specific requirements and deliver superior performance in various industries.

How to make cow manure compost

Composting is a great way to turn organic waste into nutrient-rich soil. One common material used for composting is cow manure. Cow manure is a rich source of nitrogen, phosphorus, and potassium, making it an ideal ingredient for compost. In this article, we’ll discuss the steps involved in making cow manure compost.

cow dung compost

Step 1: Collecting the cow manure The first step in making cow manure compost is to collect the cow manure. You can collect it from a local farm or buy it from a garden center. Make sure that the cow manure is well-aged and has been stored for at least six months. Fresh cow manure is too strong and can burn plants, so it’s important to let it age before using it in compost.

Step 2: Preparing the compost pile The next step is to prepare the compost pile. You can use a compost turner or create a compost pile on the ground. If you’re using a compost turner, make sure it’s at least 3 feet wide, 3 feet deep, and 3 feet tall. This will ensure that there’s enough space for the cow manure to decompose properly.

cow dung compost

Step 3: Adding the cow manure Once the compost pile is ready, it’s time to add the cow manure. Spread a layer of cow manure on the bottom of the compost pile, making sure it’s evenly distributed. Then add a layer of dry leaves or straw on top of the cow manure. This will help balance the nitrogen-rich cow manure with carbon-rich material.

Step 4: Turning the compost pile After adding the cow manure and dry leaves, it’s time to turn the compost pile. This is an important step as it helps to mix the ingredients and ensure that the compost decomposes evenly. Use a cow dung compost turner to turn the compost pile every few weeks. Make sure to mix the outer layer with the inner layer to speed up the composting process.

windrow compost turner for cow dung compost

Step 5: Watering the compost pile Cow manure compost needs to be kept moist, but not too wet. Water the compost pile regularly to keep it moist. If the compost pile is too wet, it can become anaerobic, which can slow down the decomposition process. Aim for a moisture content of around 50%.

Step 6: Checking the temperature of the compost pile As the cow manure compost decomposes, it will generate heat. Check the temperature of the compost pile regularly using a compost thermometer. The ideal temperature for composting cow manure is between 120 and 150 degrees Fahrenheit. If the temperature is too low, the compost pile may not decompose properly. If the temperature is too high, it can kill the beneficial microorganisms that break down the compost.

Step 7: Harvesting the compost After several weeks or months, the cow manure compost will be ready to use. The compost will be dark brown and crumbly, with a rich earthy smell. Use a garden fork to harvest the compost from the bottom of the pile. Spread the compost over your garden beds or mix it with potting soil to enrich it with nutrients.

In conclusion, making cow manure compost is a simple process that requires a little patience and effort. By following these steps, you can turn cow manure into a nutrient-rich soil amendment that will benefit your plants and the environment.

Of course, you can check this page for more details about how to make cow manure compost!

Cow Waste Treatment Plant

Large dairy operations produce waste, processed and managed in specialized facilities known as cow waste treatment plants. They are made to lessen the negative effects of cow waste on the environment and to encourage resource conservation. This blog post will discuss the value of cow waste treatment facilities, various approaches to treating cow waste, and the advantages of purchasing a cow waste treatment facility.

windrow type composting machine for sale

Why Are Cow Waste Treatment Plants Important?

A significant contributor to environmental damage and pollution is cow waste. It has high concentrations of nitrogen, phosphorus, and other nutrients that can contaminate surface water and groundwater supplies and cause eutrophication in aquatic ecosystems. In addition, methane and other greenhouse gases are released into the atmosphere by cow waste, which accelerates global warming.

Cow waste must be properly managed in order to have a minimal negative environmental impact. Cow manure composting facilities are here to help with this. These facilities are made to process cow waste while minimizing its negative environmental effects by removing harmful pollutants and turning them into beneficial products.

Methods of Cow Waste Treatment

There are several methods used to treat cow waste, including:

- Anaerobic digestion: This method involves dissolving cow manure without the presence of oxygen in order to create biogas, a mixture of methane and carbon dioxide. By replacing fossil fuels with biogas, which is a renewable energy source, greenhouse gas emissions can be decreased.

- Composting: This is the process of turning organic matter into compost, a rich, soil-like substance. A beneficial soil amendment, compost can be used to increase soil fertility, stop erosion, and encourage plant growth.

- Lagooning:This method involves putting cow waste in sizable, open-air lagoons. Bacteria and other organisms naturally break down the waste over time, lessening its impact on the environment.

Commercial making composting machine is help you to dispose the raw materials into fertilizer with commercial vaule.

Benefits of Investing in a Cow Waste Treatment Plant

Investing in a cow waste treatment plant has numerous benefits, including:

- Environmental Protection: By treating cow waste properly, cow waste treatment plants reduce the environmental impact of cow waste and promote sustainable resource use.

- Renewable Energy: Through the production of biogas, cow waste treatment plants can generate renewable energy that can replace fossil fuels, reducing greenhouse gas emissions.

- Soil Fertility: Compost produced by cow waste treatment plants is a valuable soil amendment that can improve soil fertility, reduce erosion, and promote plant growth.

- Cost Savings: By treating cow waste properly, cow waste treatment plants can reduce the cost of managing cow waste and promote the sustainable use of resources.

Conclusion

Cow waste treatment plants are important facilities that play a critical role in reducing the environmental impact of cow waste and promoting sustainable resource use. By investing in a cow waste fertilizer making plant, dairy operations can protect the environment, generate renewable energy, improve soil fertility, and reduce the cost of managing cow waste. Whether you are a large dairy operation or a small family farm, investing in a cow waste treatment plant is a smart decision that will benefit you and the environment for years to come.

You can check this page for more about !

https://www.manuremanagementplan.com/

How To Starting A Compound Fertilizer Plant

Creating a great compound fertilizer production line is very important when you want to produce extra high quality compound fertilizer you need for your customers. But creating a suitable compound fertilizer production line takes time and effort, and it can have its fair share of challenges. Which brings the question, what can you do to ensure everything is in place?

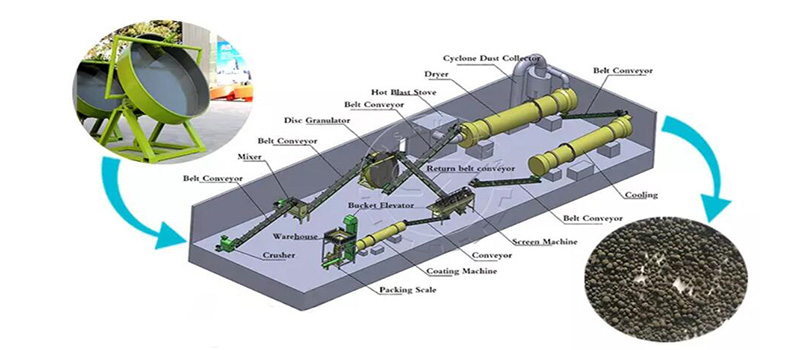

Small scale compound fertilizer mkaing line

Find a great source of raw materials

You want to work closely with people that make the complex fertilizer or you can do that on your own. That means acquiring chemical materials from various facilities. Contacting them and creating a lasting relationship with them is crucial and it will help bring in a very good result all the time. Then you can start your own compound fertilizer manufacturing business.

Identify the best plant location

These compound fertilizer production lines need to be away from residential areas, since you are generating a lot of noise. On top of that, the smell might not be ideal in residential areas either, something to think about.

Transportation is important

You will need to transport chemical material to the plant and also send the fertilizer to customers. So yes, the compound fertilizer production plant also needs transportation that ensures everything will work as expected. All the little things matter and you really need to take that into account for the best possible results and experience you can access out there. Click here to know more

what can be used in compound fertilizer production

Buy the best machines

Fertilizer machines vary when it comes to what they do and their importance. But you do want to invest in the best possible complex fertilizer equipment, as that’s what will provide you with a very good product quality all the time. In doing so, you will be very happy with the results and you can also customize the compound fertilizer production line. That’s great since it helps save time and effort, while also integrating all the necessary features that you need. SX can provide you with customerization service of complex fertilizer making system

All the little things matter when it comes to creating a compound fertilizer production line. That’s why we believe it’s crucial to take all these things into account and ensure that they are managed at the right level. Of course it takes some trial and error to do it right, but that’s what happens when you create a great compound fertilizer production line. And in the end, if will help convey incredible benefits and a wonderful experience as you start your compound fertilizer production company and deliver compound or npk fertilizer to customers. If you want to learn more about compoun fertilizer production, you can visit https://fertilizerequipmentmanufacturer.com/compound-fertilizer-production-line/

How Can Carbonization Equipment Turn Chicken Waste into High-Quality Fertilizer?

August 28, 2025

Carbon-Based Fertilizer Production, Carbon-Based Fertilizer Production from Chicken Manure, chemical fertilizer making

Comments Off on How Can Carbonization Equipment Turn Chicken Waste into High-Quality Fertilizer?

cs

Carbonization equipment offers a practical solution for the large amounts of chicken manure, bird dung, and poultry waste generated in modern farming. Unprocessed chicken waste often causes odor, environmental pollution, and nutrient loss. By applying carbonization technology, chicken manure transforms into carbon-based fertilizer with stable structure, high nutrient concentration, and long-term soil improvement benefits. During this procedure, different types of machinery cooperate to convert raw organic waste into uniform fertilizer powder, granules, or pellets. The entire processing line ensures safe preparation, effective treatment, and controlled fertilizer production.

What types of raw materials can support carbon-based fertilizer production from chicken manure?

Chicken manure always remains the core raw material for carbon fertilizer production. However, the use of additional organic and biomass materials ensures a better balance of carbon and nutrients. Many producers combine fresh chicken dung with crop straws, rice husks, sawdust, or peanut shells to improve the carbonization process. Bird manure mixed with wood chips or husk powder forms a more porous structure during carbonization, which enhances the quality of the final fertilizer.

For example, powdered corn stalk or bagasse assists the furnace in maintaining stable temperature and airflow. Mixing chicken litter with rice husk powder generates stronger carbon particles that resist breaking during granulation. Some producers also introduce animal dung from ducks, quails, or pigeons to increase organic matter content. These raw material combinations give operators flexibility to adjust fertilizer properties while ensuring that chicken waste remains the primary ingredient.

Organic Fertilizer Raw Materials

How does carbonization equipment process chicken manure into carbon fertilizer powder and granules?

The carbonization procedure involves several steps and specific machines. At the beginning, workers feed chicken manure and biomass mixtures into the carbonization furnace. The carbonization equipment heats the raw materials under controlled temperature and low oxygen, which produces carbon-rich particles instead of smoke or ash. The furnace reduces odor and pathogens, while creating powdered carbon fertilizer with stable nutrients.

After carbonization, the materials often appear as powder or small chunks. A crushing machine, for example a carbon fertilizer grinder machine for sale, refines the block into fine powder for easier mixing. This powdery structure provides a uniform base for later pelletizing. Granulation machines then play a central role. A disc granulator, flat die granulator, double roller extrusion granulator, or new type organic fertilizer granulator converts the powder into pellets or granules. Each granulator type offers different particle size and shape, but all ensure higher density and easier transportation.

Some plants also install a drying machine to reduce moisture from the granules, which strengthens their storage stability. Finally, an automatic packing machine completes the production procedure by sealing the granulated carbon fertilizer into bags, ready for distribution.

Why should producers consider integrated machinery solutions for chicken dung fertilizer production?

When chicken manure turns into carbon-based fertilizer, each machine in the line provides important support. The carbonization equipment determines nutrient stability, the crushing machine ensures powder uniformity, and the granulator decides particle quality. Without coordination, the procedure may create uneven granules, powder loss, or brittle pellets. By combining furnace, grinder, granulator, and auxiliary machines such as dryer and packer, producers achieve consistent fertilizer quality and high production efficiency.

An integrated production line also allows flexible adjustments. Operators can choose disc granulator for ball making of smaller granules, or they can select drum granulator for large-scale pelletizing. In every case, chicken dung transforms into marketable carbon fertilizer granules with precise particle size. Such flexibility directly benefits customers who require stable production, efficient procedure, and professional equipment support.

Conclusion

The transformation of chicken waste into high-quality carbon-based fertilizer always depends on the correct combination of raw materials, carbonization process, and machinery. Chicken manure mixed with biomass materials enters the carbonization furnace, then passes through crushing machines, granulators, dryers, and packing systems. Each stage strengthens the carbon fertilizer production procedure, converts powder into durable granules, and ensures long-term product stability.

For producers who expect reliable machine performance and professional guidance, a leading fertilizer equipment manufacturer such as Yushunxin provides complete solutions. With advanced carbonization equipment, efficient fertilizer grinder, and diverse granulation machinery, Yushunxin supports the full preparation, processing, and making of chicken dung carbon-based fertilizer. You can visit: https://www.charbasedfertilizermachine.com/product/chicken-dung-and-biochar-as-fertilizer/

Carbon-Based Fertilizer Productionchicken manure fertilizer production