Month: December 2025

Роликовый гранулятор: производительность и подходящие сырьевые материалы

Роликовый гранулятор в настоящее время широко применяется в производстве удобрений, химической промышленности, металлургии и других отраслях благодаря своей высокой эффективности, экологичности и низкому энергопотреблению. Для многих покупателей и пользователей при выборе роликового гранулятора наибольший интерес представляют производительность оборудования и спектр подходящего сырья. Сегодня подробно рассмотрим эти два ключевых вопроса.

1. Диапазон производительности роликового гранулятора

Производительность роликового гранулятора значительно различается в зависимости от модели, чтобы соответствовать производственным потребностям предприятий разного масштаба. Производительность главным образом зависит от размеров оборудования, ширины и диаметра роликов, а также мощности приводного двигателя.

Малые роликовые грануляторы

Основное применение — лаборатории, небольшие фермы или пробное производство на предприятиях. Обычно производительность составляет 0,5–1,5 тонн в час. Оборудование компактное, простое в эксплуатации, подходит для небольших объёмов производства и частой смены ассортимента.

Средние роликовые грануляторы

Являются основным оборудованием на большинстве малых и средних заводов по производству удобрений и химической продукции, обеспечивают производительность 2–5 тонн в час. Такое оборудование удовлетворяет потребности среднего объёма производства при разумных инвестициях и эксплуатационных расходах.

Крупные роликовые грануляторы

Используются на средних и крупных предприятиях, производительность может достигать 6–10 тонн в час и выше. Крупное оборудование обычно комплектуется автоматическими системами подачи, просеивания, упаковки и обеспечивает непрерывное, масштабное и эффективное производство.

Совет: фактическая производительность зависит также от размера частиц сырья, влажности, состава и квалификации операторов. При выборе оборудования рекомендуется учитывать реальные производственные условия и консультироваться с производителем.

2. Подходящие сырьевые материалы для роликового гранулятора

Роликовый гранулятор использует технологию сухого прессования, благодаря чему обладает высокой универсальностью по отношению к сырью. Он подходит практически для всех основных видов неорганических, органических и комплексных удобрений, а также некоторых специальных химических и строительных порошков. Основные типы подходящего сырья:

Сырье для удобрений

Азотные удобрения: мочевина, аммиачная селитра, карбонат аммония и др.

Фосфорные удобрения: моноаммонийфосфат, диаммонийфосфат, суперфосфат и др.

Калийные удобрения: хлорид калия, сульфат калия и др.

Прочие: комплексные удобрения, BB-удобрения, удобрения с замедленным высвобождением и др.

Органические удобрения

Животный навоз: куриный, коровий, свиной и другие, предварительно прошедшие ферментацию и высушенные в порошок

Солома, жмых, древесные опилки и другие органические вещества в порошкообразной форме

Городской осадок сточных вод, органическое сырьё из бытовых отходов (после предварительной обработки и обезвреживания)

Химическое и другое сырьё

Кормовые добавки, премиксы и другие порошкообразные материалы для кормов

Минеральные порошки, металлургические порошки, оксид железа, металлические порошки и др.

Строительные материалы в виде порошка, гипс, обезсерненный гипс и др.

double roller compactor granulator design

Требования к сырью

Роликовый гранулятор особенно эффективен для порошкообразных материалов с низким содержанием влаги (обычно ≤8%) и хорошей текучестью. Если частицы сырья слишком крупные — их необходимо предварительно измельчить; если сырье слишком влажное — требуется сушка, чтобы обеспечить качество гранул и выход годной продукции.

Роликовый гранулятор охватывает широкий диапазон производительности — от лабораторных до промышленных масштабов, а также способен обрабатывать самые разнообразные виды сырья для удобрений и химической промышленности. При выборе оборудования пользователям рекомендуется учитывать свойства исходного сырья, технологический процесс и требуемую производительность, а в случае нестандартного сырья — обращаться к производителю для проведения испытаний и подбора оптимального решения.

Если вы хотите узнать больше технических деталей о роликовом грануляторе, примеры внедрения или проконсультироваться по подходящему сырью, оставляйте комментарии или звоните нам! Для получения более подробной информации, пожалуйста, посетите:https://www.sxmashina.com/rolikovyy-granulyator/

How to Produce High-Quality Compost from Organic Waste: Practical Methods That Work

Turning organic waste into high-quality compost is a proven way to improve soil health while reducing disposal costs. However, not all compost is created equal. Poor preparation, improper material balance, or uncontrolled decomposition often lead to unstable compost with low nutrient value. To achieve consistent, market-ready compost, both the preparation stage and the composting method matter.

Selecting and Preparing Organic Waste Materials

The quality of compost starts with raw material selection. Common organic waste used for compost production includes livestock manure, crop residues, food waste, garden waste, and agro-industrial by-products. These materials differ in moisture content, carbon-to-nitrogen ratio, and particle size.

Before composting begins, raw materials should be pre-treated. Shredding or crushing organic waste increases the surface area and improves microbial access. Moisture adjustment is also essential—most composting processes work best when moisture content is controlled within a suitable range. This preparation stage lays the foundation for stable organic waste composting and efficient biodegradation.

Balancing Carbon and Nitrogen for Stable Composting

One of the most critical factors in making high-quality compost is achieving a balanced carbon-to-nitrogen ratio. Carbon-rich materials such as straw, sawdust, or rice husk provide structure, while nitrogen-rich inputs like manure or food waste support microbial growth.

An unbalanced mix can slow decomposition or cause odor issues. Proper blending creates ideal conditions for aerobic composting and ensures the final bio organic compost is mature, nutrient-rich, and safe for agricultural use.

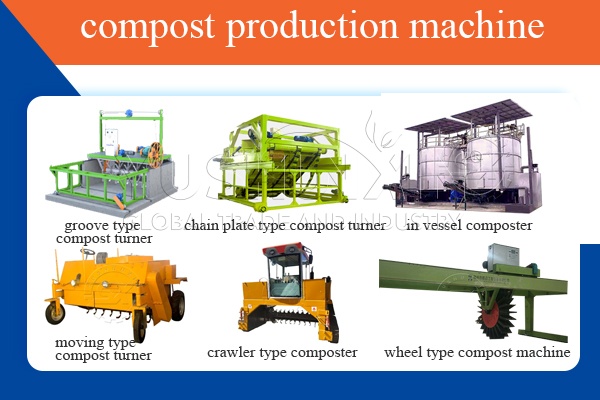

Choosing the Right Composting Method

There are several proven composting methods for organic waste recycling. Windrow composting is widely used for its simplicity, while aerated static piles offer better oxygen control. In more industrialized settings, in-vessel composting systems and controlled composting units provide faster processing and higher consistency.

Regardless of the method, oxygen supply, temperature control, and regular turning are key to producing high-quality organic compost. Maintaining proper airflow prevents anaerobic zones and helps achieve uniform decomposition throughout the pile. Learn more!

composting method and equipment

Monitoring Temperature and Maturity

Temperature is a direct indicator of microbial activity during composting. High temperatures help destroy pathogens and weed seeds, while gradual cooling signals compost maturity. Regular monitoring ensures the composting process stays on track.

Mature compost should have a stable structure, earthy smell, and uniform texture. At this stage, the material is suitable for use as organic soil amendment, biofertilizer input, or further processing such as screening and granulation.

Preparing Compost for Downstream Applications

High-quality compost is often used as a base material for fertilizer production. After composting, screening removes oversized particles, and additional processing can improve consistency for commercial applications.

By combining proper preparation, controlled composting methods, and careful monitoring, organic waste can be efficiently transformed into valuable compost products. This approach not only improves fertilizer quality but also supports scalable and sustainable compost production. If you want to invest the compost turners, welcome to visit: https://www.fertilizerequipmentprice.com/industrial-composting-machine/

Chicken Manure Biofertilizer Production Process: Transforming Waste into Agricultural Gold

The poultry industry generates millions of tons of chicken manure annually, presenting both environmental challenges and opportunities. Through advanced biofertilizer production technology, this waste stream can be transformed into nutrient-rich organic fertilizer, creating a sustainable circular economy solution for modern agriculture.

The Production Process: From Waste to Resource

Our state-of-the-art chicken manure biofertilizer production line follows a meticulous multi-stage process designed to maximize nutrient retention while ensuring pathogen elimination. The journey begins with raw material preparation, where fresh chicken manure is collected and mixed with carbon-rich materials like straw or sawdust to achieve the optimal carbon-to-nitrogen ratio of 25:1 to 30:1.

The fermentation stage represents the heart of the process. Using advanced composting technology, the mixture undergoes controlled aerobic decomposition in specialized fermentation facilities. Temperature monitoring ensures the pile reaches 55-65°C for 72 hours, effectively eliminating harmful pathogens including E. coli and Salmonella while preserving beneficial microorganisms. Regular turning every 3-7 days maintains optimal oxygen levels, accelerating decomposition and preventing odor development.

Following fermentation, the mature compost is crushed into fine powder using high-efficiency crushers, ensuring uniform particle size of ≤2mm. This powder then enters the granulation phase, where specialized equipment transforms it into uniform 4-6mm pellets using disc or rotary drum granulators. The granulation process enhances fertilizer handling, storage, and application while providing slow-release properties that improve nutrient utilization efficiency.

YUSHUNXIN can provide you with the complete chicken poop processing equipment, welcome to contact us !

Quality Control and Packaging

The production line incorporates comprehensive quality control measures throughout each stage. Screening equipment separates qualified granules from oversized or undersized particles, while drying and cooling systems reduce moisture content to optimal levels for storage. An optional coating process can be applied to enhance granule strength and prevent caking during storage.

The final product undergoes rigorous testing for nutrient content, organic matter percentage, and microbial activity before automated packaging systems prepare it for distribution. The resulting biofertilizer contains essential nutrients including nitrogen, phosphorus, and potassium, along with beneficial microorganisms that enhance soil health and plant growth. Learn more!

Environmental and Economic Benefits

This advanced chicken manure biofertilizer production technology offers significant environmental advantages by converting waste into valuable agricultural inputs while reducing greenhouse gas emissions and water pollution risks. The process supports sustainable farming practices by improving soil structure, enhancing water retention, and promoting beneficial microbial activity in agricultural soils.

For poultry operations, implementing this biofertilizer production line creates additional revenue streams while addressing waste management challenges. The technology represents a win-win solution that benefits farmers, the environment, and the agricultural sector as a whole, contributing to a more sustainable and circular agricultural economy. If you need a business plan, welcome to visit: https://www.biofertilizerproduction.com/product/solution-for-using-chicken-poop-as-biofertilizer/

Годовая акция | Специальное предложение на оборудование для производства гранулированных минеральных удобрений — бесплатный проект!

Вот и подходит к концу еще один год. В знак благодарности за доверие и поддержку наших клиентов мы запускаем специальную годовую акцию на оборудование для производства гранулированных минеральных удобрений! Независимо от того, строите ли вы новый завод или обновляете существующее производство, сейчас самое выгодное время для покупки. К тому же — бесплатное проектирование производственной линии именно под ваши задачи!

Линия-по-производству-минеральных-удобрений

I. Годовая акция — поддержка модернизации вашего бизнеса

В период действия акции при заказе нашего оборудования вы получаете:

– Специальные цены: отдельные модели оборудования по сниженной цене, дополнительные скидки при покупке полной линии;

– Бесплатное проектирование: опытный инженер индивидуально разработает проект с учетом вашей площади, сырья и требуемой производительности — бесплатно;

– Бесплатные запасные части: ключевые расходники прилагаются к оборудованию для бесперебойной работы;

– Приоритетная отгрузка: клиенты, заключившие договор, получают приоритет при производстве и отправке, монтаж возможен до конца года;

– Техническая поддержка на месте: команда специалистов установит, настроит оборудование и обучит персонал.

II. Преимущества нашего оборудования

– Интеллектуальное управление: вся линия оснащена системой интеллектуального управления PLC, что делает производство эффективнее и проще;

– Универсальность по сырью: подходит для переработки разных видов минеральных, смешанных и органоминеральных удобрений;

– Высокая степень грануляции и равномерность: оптимизированная конструкция гарантирует отличный внешний вид и стабильные свойства гранул;

– Экологичность: низкое энергопотребление и минимальные выбросы отвечают современным экологическим требованиям;

– Надежное сервисное обслуживание: оперативная поддержка 24/7, пожизненное техническое сопровождение.

III. Бесплатное проектирование — индивидуально для каждого

У каждого клиента свои задачи: состав сырья, целевая производительность, особенности помещения. Наши инженеры бесплатно разрабатывают индивидуальную схему производственной линии:

– Выбор и компоновка оборудования

– Балансировка производительности и потоков

– Оптимизация использования пространства

– Решения по энергосбережению и экологии

Инвестируйте с умом — исключите доработки и издержки!

IV. Как принять участие

Срок акции: с настоящего момента до 31 декабря 2025 года

Как участвовать:

– Позвоните по телефону или оставьте заявку на сайте — расскажите о своих задачах

– Назначьте встречу с инженером (на месте или онлайн)

– После согласования проекта подпишите договор и получите все акции и бесплатные услуги

Конец года — самое время для обновления производства! Не упустите шанс приобрести профессиональное оборудование для гранулирования минеральных удобрений по специальной цене и получить бесплатно индивидуальный проект. Увеличьте производительность и заложите фундамент для успеха в новом году!

Оставьте заявку или позвоните нам — получите спецпредложение и индивидуальное решение уже сегодня! Для получения более подробной информации, пожалуйста, посетите:https://www.granulyator.com/product/liniya-granulirovaniya-mineralnoe-udobreniya/

Wet vs. Dry Granulation Techniques in Biofertilizer Production: A Practical Comparison for New Manufacturers

In the biofertilizer industry, choosing the right granulation method—either wet granulation or dry granulation—plays a major role in determining pellet quality, production cost, and overall plant efficiency. Whether a producer is building a new biofertilizer pellets manufacturing line or upgrading existing equipment, understanding the difference between these two granulation technologies is essential. Below is a clear comparison to help new fertilizer investors make informed decisions.

1. What Is Wet Granulation in Organic Fertilizer Making?

Wet granulation is widely used in bio-organic fertilizer production, especially when working with composted manure, microbial inoculants, or humic-acid-based materials. The process involves adding liquid binders (water, microbial solution, or steam) to increase moisture and allow materials to agglomerate into round pellets.

Common equipment includes:

disc pelletizers (pan granulators)

rotary drum granulators

new-type organic fertilizer granulators

Wet granulation is known for producing spherical, uniform, and highly attractive granules, making it ideal for commercial organic fertilizers. However, because moisture increases during the process, the pellets must go through dryers and coolers, which add to energy consumption.

rotary drum granulation machine

2. What Is Dry Granulation for Biofertilizer Pellets?

Dry granulation—or press granulation, roller compaction, or extrusion granulation—forms pellets by compressing powder materials without adding additional moisture. It is commonly carried out using a double roller granulator (also called a compactor or extrusion granulator).

Key advantages include:

minimal energy consumption

no need for drying equipment

ideal for heat-sensitive probiotics or microbial biofertilizers

compact layout suitable for small or medium-scale plants

Dry granulation produces dense, oval or pillow-shaped pellets, which are mechanically strong but may be less uniform in appearance compared with wet granules.

3. Quality Differences and Application Preferences

Wet granulation is preferred when producers need:

round granules with high aesthetic value

pellets with adjustable nutrient release rates

strong binding capability for low-viscosity materials

Dry granulation is recommended for:

materials already containing natural moisture

microbial fertilizers requiring low-temperature processing

investors seeking a low-cost granulation line with fewer machines Click here to get more!

4. Cost and Equipment Considerations

Wet granulation lines require more machines—such as mixers, granulators, rotary dryers, coolers, and coating machines—which increases investment.

Dry granulation systems are simpler and often only need a crusher, mixer, roller press granulator, and screening machine, resulting in lower operational costs.

Conclusion

Both wet and dry granulation offer reliable ways to produce biofertilizer pellets, but the right choice depends on budget, raw materials, and product requirements. For manufacturers planning a new biofertilizer production line, understanding these technical differences helps optimize efficiency and achieve high-quality pellet output. If you want to know more, welcome to visit: https://www.biofertilizerproduction.com/product/bio-fertilizer-granulator/

Raw Material Moisture Control for Stable Disc Granulation Performance

December 24, 2025

bio fertilizer making machine manufacturers, disc granulation line, disc granulator, Disc Granulator for Bio Fertilizer Production, disc pelletizer manufacturing line

Comments Off on Raw Material Moisture Control for Stable Disc Granulation Performance

cs

In biofertilizer and organic fertilizer production, disc granulation is widely used due to its flexible operation and good control over particle size. However, one of the most critical factors affecting stable disc granulating performance is raw material moisture. Improper moisture content often leads to poor granule formation, excessive fines, or unstable pellet size distribution.

Understanding moisture control requirements is essential for anyone operating a disc granulator, also known as a pan granulating machine, disc pelletizer, or plate granulator.

Why Moisture Matters in Disc Granulation

Disc granulation relies on rolling and layering mechanisms rather than mechanical compression. During rotation, fine particles gradually adhere to each other through surface tension and capillary forces created by water.

If the raw material moisture is too low, particles fail to bond effectively, resulting in dust, weak pellets, or no granulation at all. On the other hand, excessive moisture causes material to stick to the disc surface, form oversized lumps, or collapse into slurry. Therefore, moisture balance directly affects granule strength, uniformity, and production stability in a disc granulation system.

Recommended Moisture Range for Biofertilizer Materials

For most bio organic fertilizer raw materials—such as composted manure, fermented organic waste, or bio-based powder blends—the ideal moisture content before disc granulation typically falls between 20% and 30%.

Below 18%, granulation efficiency drops sharply

Between 22%–28%, granules form smoothly and grow uniformly

Above 32%, material flow becomes unstable and difficult to control

The exact moisture window depends on particle size distribution, organic matter content, and binder usage, which is why moisture adjustment is often done gradually during operation. Learn more!

disc pelletizer for biofertilizer production

How Moisture Is Adjusted During Disc Pelletizing

In practical production, moisture control is rarely achieved by pre-mixing alone. Most disc granulating machines are equipped with water spraying systems that allow operators to fine-tune moisture during pellet growth.

Uniform spraying is critical. Local over-wetting can cause uneven granule sizes, while insufficient spraying leads to excessive recycling of fines. In larger biofertilizer disc granulation lines, moisture adjustment is often combined with material pre-conditioning using mixers or aging bins.

Interaction Between Moisture and Disc Parameters

Raw material moisture does not work independently. It interacts closely with disc angle, rotational speed, and feed rate. Higher moisture generally requires a slightly lower disc angle or slower rotation to maintain stable rolling behavior.

Operators often find that stable disc granulating performance is achieved through coordinated adjustment rather than relying on moisture control alone.

Common Moisture-Related Problems and Solutions

Unstable pellet size, high return material ratio, and poor granule hardness are often linked to moisture imbalance. Regular moisture testing, controlled spraying, and consistent raw material preparation help maintain stable operation in disc granulator-based fertilizer production lines.

Final Notes on Stable Disc Granulation

Effective moisture control is not about hitting a fixed number, but maintaining a controllable range throughout production. For biofertilizer manufacturers using disc pelletizers, mastering raw material moisture management is key to achieving consistent granule quality and long-term production stability. If you need a high-quality pan granulator, welcome to visit: https://www.biofertilizerproduction.com/product/disc-pelletizer-for-biofertilizer-making/

disc granule making machine