Tag: organic fertilizer production line

What Is The Best Solution Of $35000 Powder Organic Fertilizer Production Line Design?

Some of the best powder organic fertilizer production line designs are going to cost a substantial amount of money. You may pay as much as $35,000 for one of them. It did you happen to have one of these top-rated models, you will see a definite improvement in your output and production. Even if you spend the money, you may still be wondering if that is the best solution for you. Perhaps there are less expensive models that can provide you with the output you are expecting. Here is the best solution for using this expensive type of powder organic fertilizer production if that is what you would like to invest in.

Small Scale Organic Fertilizer Plants

What Do These Machines Do?

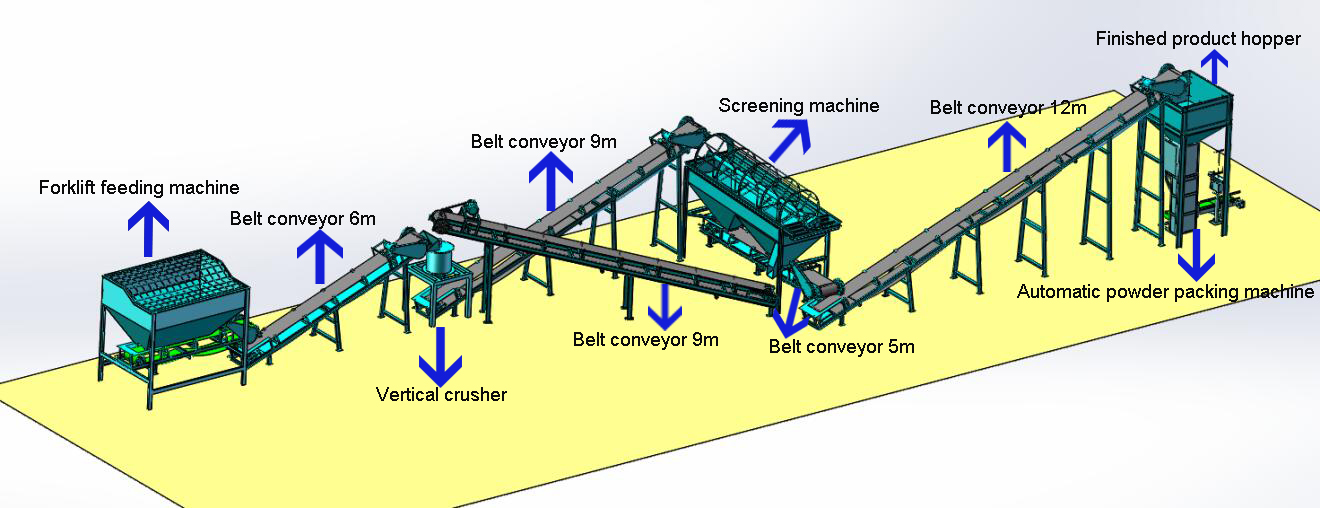

First of all, these are very elaborate setups. They can take up quite a bit of space. This is especially true for customized compost fertilizer machines that can also be a granulator at a manufacturing plant. They are designed to not only mix up the material but also process, leading to the pellets that will be produced. The more elaborate they are, and the more volume they can handle, you are simply going to pay a higher price for these advanced systems.

Are These The Best Solution For Your Business?

There are several things to consider before making this type of investment. First of all, the production line itself is quite large. If you have limited space at your facility, you may want to consider getting something that is smaller, yet may be able to produce a comparable amount of pellets. Second, if this is not a large investment for you, you must consider whether or not it is the best machinery. In some cases, a powder organic fertilizer production process will involve not only composting, but also the crushing, sieving, and the packaging of this material. If that is what you are looking for, the system would be the right fit for your business.

commercial cow dung powder making machine

How To Find Them At A Lower Price

Instead of getting this type of system, you may want to consider a granulator organic fertilizer. These can be less expensive and also help you need your production quota. This will involve the mixing, granulation, and the cooling and drying of the product. Keep in mind that the powder organic fertilizer production process is slightly different and may not produce the exact final product that you want. As you speak with the different companies, it will be easy to determine if spending this amount of money is the right choice for you.

There are so many production lines that work with composting material. You just have to choose one that will provide you with compost fertilizer that you require. Doing this manually, or trying to accomplish all of this without such a concise system, will slow down the process of producing the compost that you need. Eventually, through talking with many different businesses, you may find that spending $35,000 on a powder organic fertilizer production line is a good deal. It will be even better when to start to use the material you are producing, or it may allow you to sell more of this material than ever before.

How To Commercially Manufacture Organic Fertilizer From Animal Manure

For centuries animal manure has been a traditional source of nutrients for agricultural use. An organic fertilizer production line can process organic waste such as animal manure and turn it into organic fertilizer. Farm use of organic fertilizer is key to the development of ecological agriculture. Most of the essential nutrients and elements for plant growth are contained in organic fertilizers, however, it is difficult for plants to use it directly. Composting allows the nutrients to be released, improving soil structure and productivity that make it possible for plants to absorb the nutrients.

Different Types of Materials used in Organic Fertilizers

There are several different types of materials that can be used in a fertilizing production machine to produce organic fertilizer:

• Livestock and poultry waste and manure from cattle, sheep, horses, and rabbits

• Agricultural waste such as soybean meal, cotton meal, and straw

• Industrial wastes such as wine, vinegar, sugar, cassava, and furfural lees

• Urban sewage and river sludge

Organic fertilizing machines are available in small, medium, and large scale sizes.

Types of Organic Fertilizers

We have two types of organic fertilizer production lines available to turn animal manure into fertilizer – organic powder fertilizer and granular fertilizer production line flow. Both will produce high-quality organic fertilizer.

Organic Powder Making Fertilizer Production Line

Organic manure fertilizer powder is one of the simplest fertilizer-making systems compared to a complete production line in a factory. The machine is capable of manufacturing fine powder fertilizer from organic substances.

The organic powder fertilizer production flow line includes the following components:

commercial cow dung powder making machine

– Fertilizer compost turner

– Fertilizer granulator

– Fertilizer crusher

– Fertilizer screening machine

– Fertilizer drying and cooling machine

– Cyclone fertilizer dust collector

– Packing scale

– Coating machine

– Fertilizer bagging machine

The powder fertilizer production line is cost-effective as it reduces the amount of manual labor required. The cost can be further reduced by replacing the fertilizer bagging machine with manual labor.

The capacity of the powder fertilizer machine ranges from 1 t/h to 20 t/h depending on your particular requirements.

Granular Organic Fertilizer Production Machine

Granular fertilizer production flow process is more complicated than the powder fertilizer making process. Lately, the pellet fertilizer process has become much more popular around the world. The size and increased weight of the pellets make it easier to handle and use and certain inorganic elements can be added to improve the effectiveness of the fertilizer. Adding these elements to powder fertilizer can cause moisture absorption and agglomeration.

Industrial vermicomposting granules equipment

There are three steps involved in the complete granular organic fertilizer making process:

1. Pre-Treating Process – this is the first step in the fertilizing production line that prepares organic compost for agricultural use. The organic fertilizer compost turner component of the machine is used in this phase of the process.

2. Pelletized Organic Fertilizer Process – in the second phase of the process the organic fertilizer granulator is used as well as the drying and cooling machine.

3. Post Processing – in the post-processing phase the fertilizer screening machine is used together with the organic fertilizer polishing machine. Optional fertilizer bagging equipment is also available if required.

In addition, we are able to provide you with a customized organic fertilizer production line flow if that is what your operation requires.

What Do You Need to Establish an Organic Fertilizer Production Line

April 13, 2023

making organic fertilizer, manure recycling, organic fertilizer granulator, Organic fertilizer making line, Organic fertilizer manufacturing, organic fertilizer manufacturing process, Organic Fertilizer Producing, Organic Fertilizer Production, Organic Fertilizer Production Line, organic fertilizer production machine, Organic Fertilizer Wet Granulating, Organic Waste Compost

Comments Off on What Do You Need to Establish an Organic Fertilizer Production Line

cs

For environmentally conscious and sustainably operated agriculture, organic fertilizers are growing in popularity. Given the rising need for organic fertilizers, it’s critical to comprehend the procedures for setting up a production line for organic fertilizers. It is crucial to comprehend the tools and supplies required to make organic fertilizer as well as the rules governing its manufacture.

Organic fertilizer production is a booming industry, with demand for natural and sustainable fertilizers growing rapidly. If you are looking to establish an organic fertilizer production line, there are several factors you need to consider to ensure that your production process is efficient, sustainable, and profitable.

compost machine for converting manure into organic fertilizer

Raw Materials

The first thing you need to consider is the raw materials that you will be using to produce your organic fertilizer. Chicken manure, cow manure, horse manure, and other animal waste are popular raw materials for producing organic fertilizers. You may also consider using food waste, yard waste, and other organic waste materials to create a diverse and sustainable organic fertilizer plant product.

Equipment

The next step is to determine the equipment you need to produce your organic fertilizer. This may include composting equipment, granulation equipment, mixing equipment, and drying equipment. When selecting equipment, it is important to consider factors such as capacity, energy efficiency, and ease of operation.

Processing

A well-planned processing line is essential for producing organic fertilizer of the highest caliber. These processes could involve composting, granulation, mixing, drying, screening, and packaging. It is important to maximize efficiency and reduce waste at every stage of the production process.

Quality Control

In the process of producing organic fertilizer, quality control is essential. To make sure that your organic fertilizer satisfies consumer needs and meets industry requirements, you should implement a stringent quality control procedure. Lab tests, visual inspections, and routine audits of your production process may all fall under this category.

organic fertilizer making machine

Packaging

Packaging is an important consideration for organic fertilizer production. You should choose a packaging material that is durable, easy to handle, and environmentally friendly. You may also want to consider offering different packaging sizes to meet the needs of different customers.

Marketing and Sales

Marketing and sales are critical components of establishing a successful organic fertilizer production line. You should develop a marketing plan that targets your target market and promotes the benefits of your organic fertilizer. You should also establish a strong sales network that includes distributors, retailers, and end-users.

Legal and Regulatory Compliance

Finally, you should consider the legal and regulatory requirements for organic fertilizer production. This may include obtaining permits, registering your business, and meeting environmental and safety regulations.

Conclusion

Establishing an organic fertilizer production line requires careful planning and attention to detail. By considering these key factors, you can ensure that your production line is efficient, sustainable, and profitable. Whether you are a small-scale farmer or a large-scale fertilizer producer, with the right approach and the right equipment, you can create a thriving and successful organic fertilizer production line.

You can check our website for more about our products!

design of organic fertilizer production linemachie used in organic fertilizer production lineorganic fertilizer production line